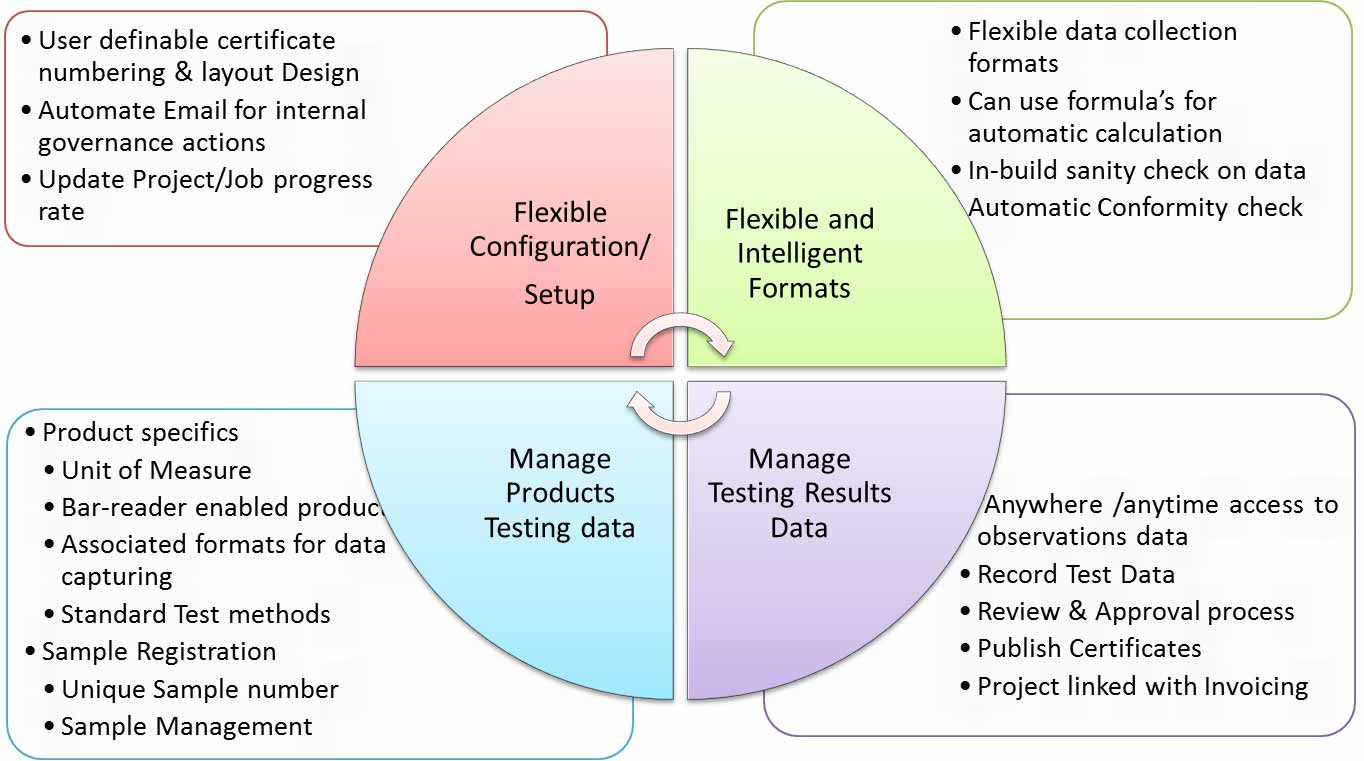

SmartTesting LIMS key features

1. With Smarttesting LIMS, testing assignments are created automatically with the order receipt,

2. Project can be created for execution of testing assignments

3. Each sample is a registered separately and as a separate task in pending jobstray could be assigned to separate department and test engineers

3.1 Unique Barcode generated for easy tracking of sample

3.2 Customisable Label printing specific to printer and stationary used for labels

4. After the testing is complete, results could be logged on the database

5. Results could be reported in tailor-made templates (could be as much similar to your existing formats)

6. All samples reports could be invoiced distinctly with references of report numbers in each invoice line, thus speeding up reconciliation with customer accounting staff and lab accounting function

7. All internal communications are Emails based, thus speeding up internal processes and removing bottleneck

8. Automatic project progress percentage update depending on milestone definitions thus management is always close to on-ground status of all test assignments

9. Adjustment of sample within the workflow as per lab specific test procedure

10. Manage regent stock and get automatic alert when stock is lower then min. level

11. View instrument allocation and resource workload distribution

SmartTesting : Key Benefits

SmartTesting is a LIMS for testing lab industry, it is intelligently integrated with Customer relationship management software. All the changes to the test data are logged to support the audit exercise. Following are the key benefits could be realized by companies using SmartTesting LIMS Module.

- Reduction in operator cost as observations can be entered directly by engineers thus resulting in improvement of productivity

- Reduction in silly clerical mistakes passing through to customers

- Reducing paper usage (records in paper format from test results to test reports)

- Reducing lag time (can deliver test reports faster with better quality as process hangover reduced significantly )

- Reducing communication overhead cost

- Integrated single view of all projects and jobs associated with customer order

- Reduction in traveling cost as engineer get feedback on test results at the same time after submission for approval

- Manage your lab resources (staff/regent/instrument) efficiently

- Increasing customer satisfaction

- Single view of all labs to the management, thus enabling management to draft strategies and work distribution accordingly

- Optimisation of workload across different labs, equitable distribution to all engineers, reducing idling time

Now available approver’s dasboard i.e. approvers can approve test results waiting for their authorisation as a matter of few clicks.

SCC is offering QMS/CAPA module that has been integrated with the Material Testing LIMS to help QA departments of quality focused manufacturing organizations thus will make SCC LIMS single product to cover all their operations Click here to see details

Contact us for free online demo/trial user or onsite demo that could be arranged at convenient time depending on place, time and availability.

Pages also seen with this articles are

Detailed features of SCC Lab Information System (LIMS)

Commercial Proposition for LIMS

Paperless Laboratory, Facing Audits without paper crunching